What is Laser Beam Profiler with M2 platform software “LaseView” ?

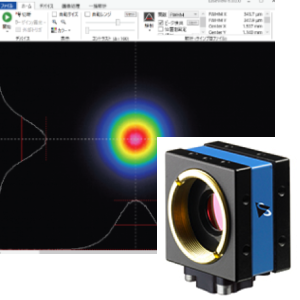

Laser Beam Profiler with M2 platform software “LaseView” is a highly functional and versatile laser Beam Profiler software that allows to use commercially available CCD cameras as Laser Beam Profiler.

By using commercially available CCD and CMOS cameras, it is easy to build an extremely low-cost and practical beam measurement system

Our software suite is optimized not only for small-aperture beam profilers but also for large beam profiler systems. From raw image acquisition to profile analysis, the tools support full-aperture data from LBP-B series instruments.

Features

- Easy measurement of beam profile and beam diameter.

- Low cost commercial available cameras can be used

▶︎ possible to build low cost beam monitoring system. - Measurement of M2 beam quality.

- Measurement of beam divergence.

▶︎ Measurement of propagation loss. - Measurement of temporal beam pointing changes.

▶︎ Measurement of beam stability. - Save images at set time intervals (image logging).

- Free evaluation version is available.

- Micro-beam (from 2 μm) measurement set is available for measurements.

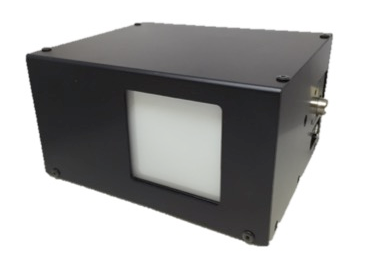

- Laser Beam Profiler for large apertures (up to 200 mm) and high power.

- One software license for one computer

- Multiple cameras can be connected to a single software

Price

| version | Product name | Price (Excluding tax) |

Delivery date | User’s manual |

|---|---|---|---|---|

| Evaluation (7 days) |

LaseView 7-day Evaluation | Free of charge | Immediately |

|

| Commercial | LaseView Permanent License | Contact us | Immediately |

Details

*At least a camera is required to measure the beam profile. Please see the “recommended cameras“.

*If the beam intensity is too strong or the beam diameter is too small, please see the “Other options“.

*For large beam diameters, please see “Laser Beam Profiler for large aperture and high power“.

*If the image does not appear when the start button is pressed, set the camera settings in the [Pixel Format] of the [Camera Settings] tab before starting.

Features

- Ribbon UI User Interface

- Image Logging Function

- Analysis of temporal beam pointing change

- Beam divergent angle analysis

- Histogram Display

- Measure spatial intensity distribution of the beam

- Measurement of beam diameter

- Measurement of M2

- Measurement of small beam sizes below 30 μm

- Real-time image averaging

- Real-time contrast adjustment(wide dynamic range of 16 bit, 65536 shades)

- Image buffer function (images can be stored in memory and displayed sequentially)

- Image saving function in TIFF format

- Smooth display with hardware acceleration

- Support for 32 bit and 64 bit Windows

System Requirements

- Windows 8.1, Windows 10, Windows 11

- CPU speed: Intel Core i3 2GHz or equivalent or higher

- Free memory: 512MB or more

*However, we do not guarantee the operation of all computers that meet this environment.

*NET Framework 4.5 or higher is required to run this software.

You can check the version of .NET Framework version from the following link:

http://msdn.microsoft.com/ja-jp/library/hh925568(v=vs.110).aspx

*Depending on the version, the actual screen may differ from the screen in this manual, but it can be used without problems.

Analysis function

- Line profile

Crosshair line profile display with Gauss, Lorentz and Sech function fitting and FWHM analysis - Integration Profile

Display of horizontally and vertically averaged profiles (with the same analysis functions as the line profile) - Maximum value projection profile (Max. Intensity Projection)

Display of horizontally and vertically averaged (maximum) projection profile

(with analysis function similar to line profile) - Point-to-Point Distance

Measure the distance between any two points on the screen. - Peak Integration

Analyzes the integrated value inside the circle and the light intensity on the cursor with the outside of the circle as background.

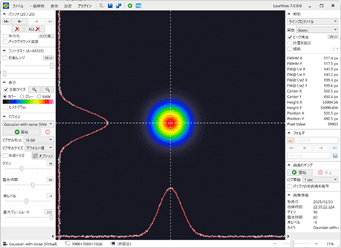

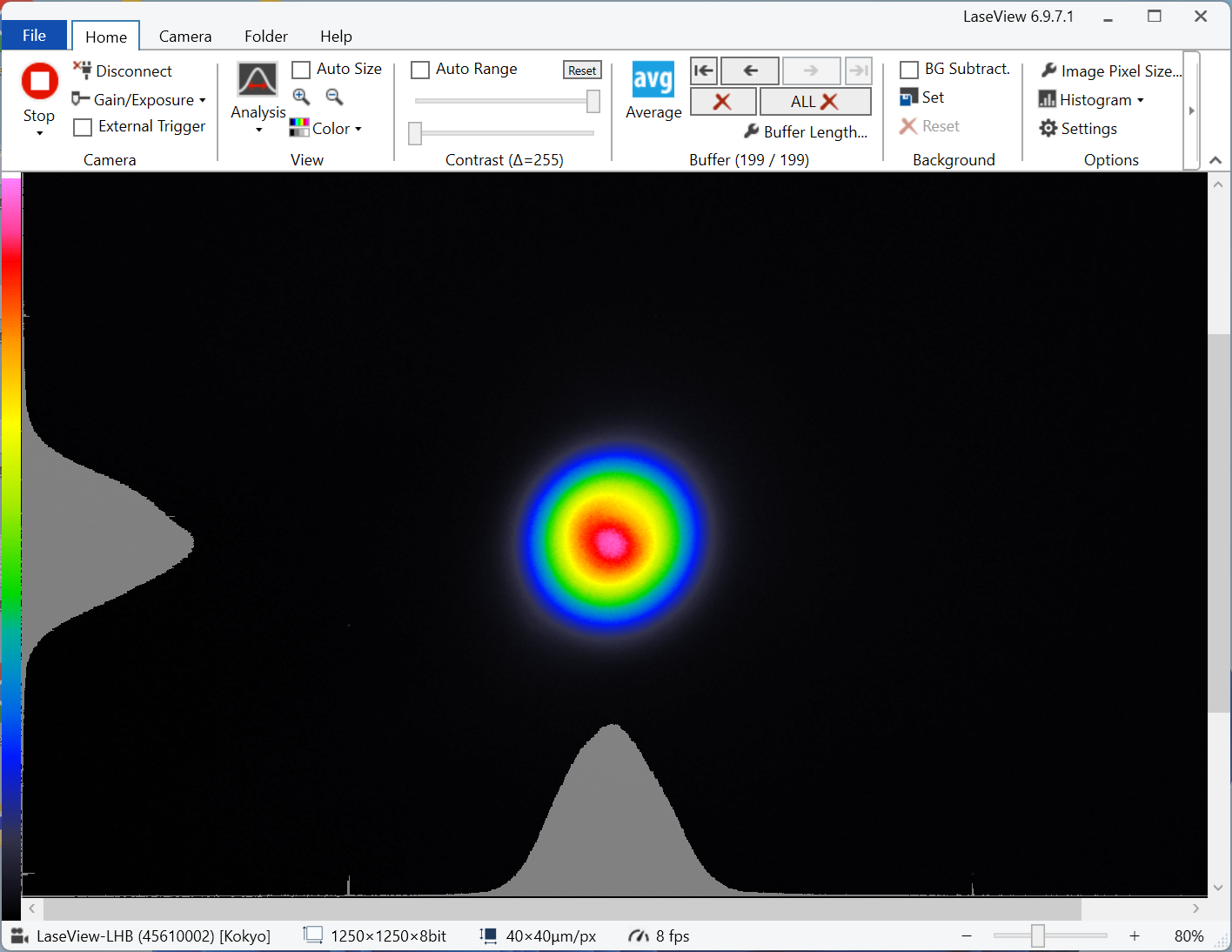

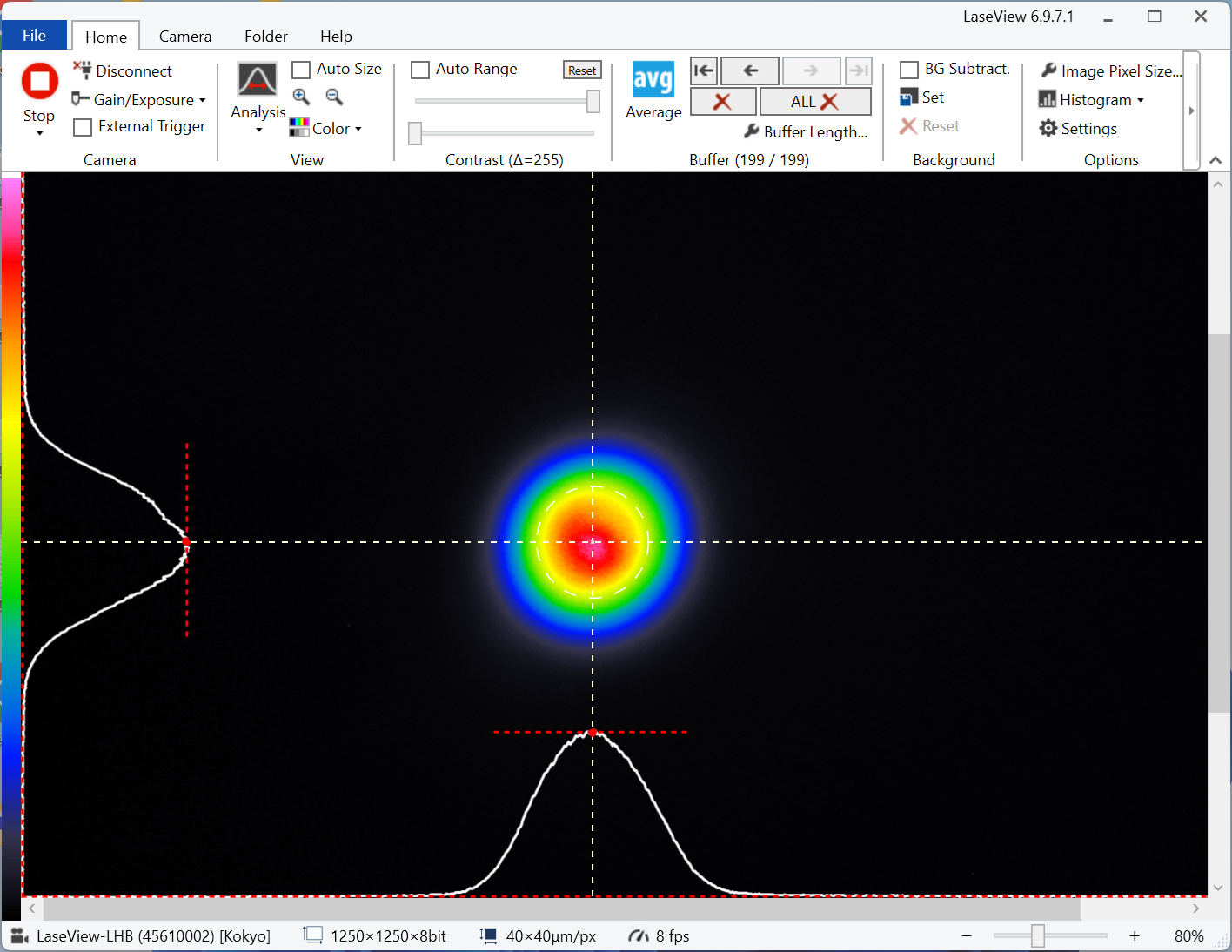

Example of analysis

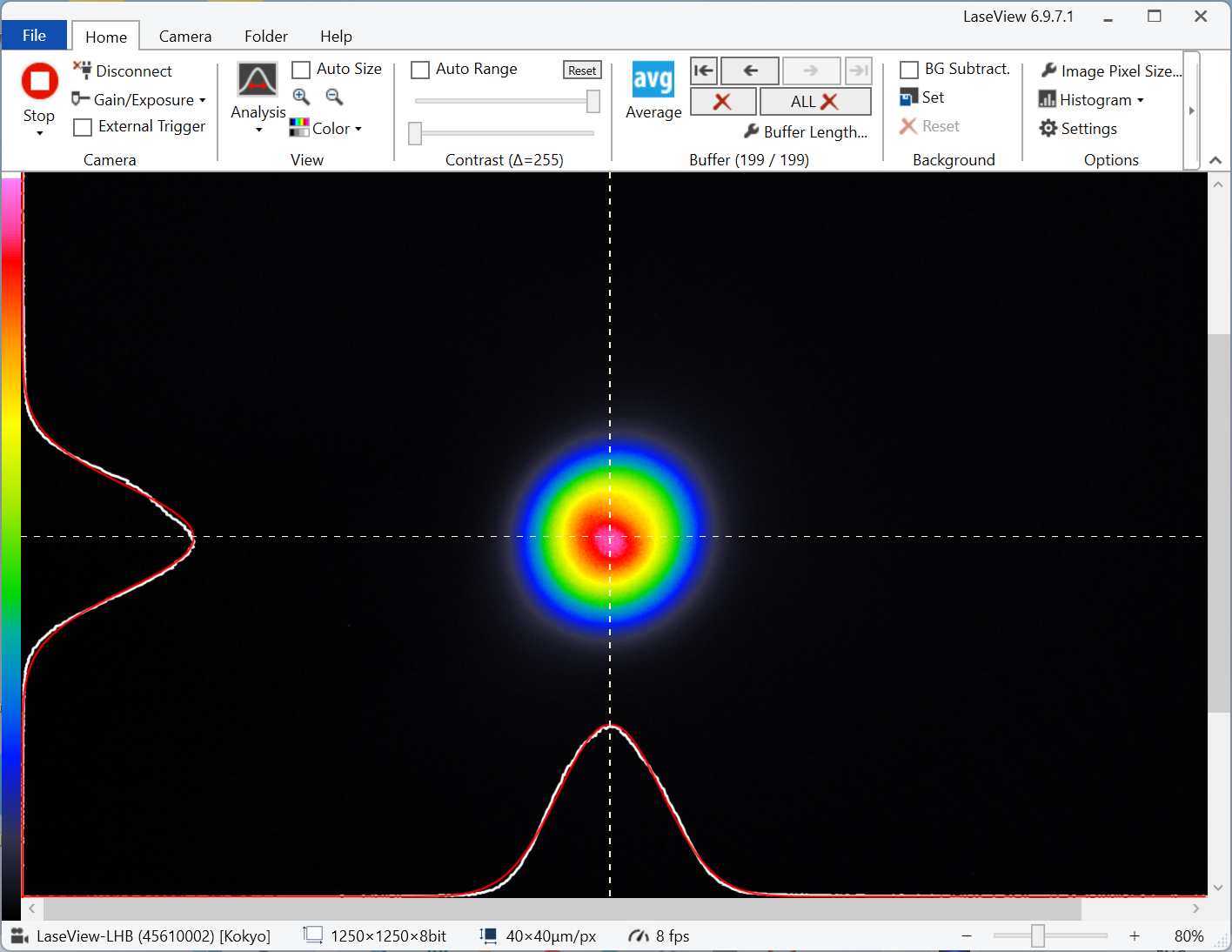

Line profile function

Displays the line profile on the crosshairs (white line). The FWHM of the beam profile can be calculated and fitted with Gauss, Lorentz, and Sech functions. The crosshairs can also be rotated (the red line is the result fitted with the Sech2 function).

This video is a demonstration of the real-time tracking of peaks in LaseView’s line profile analysis mode, with the peak detection check box turned on.

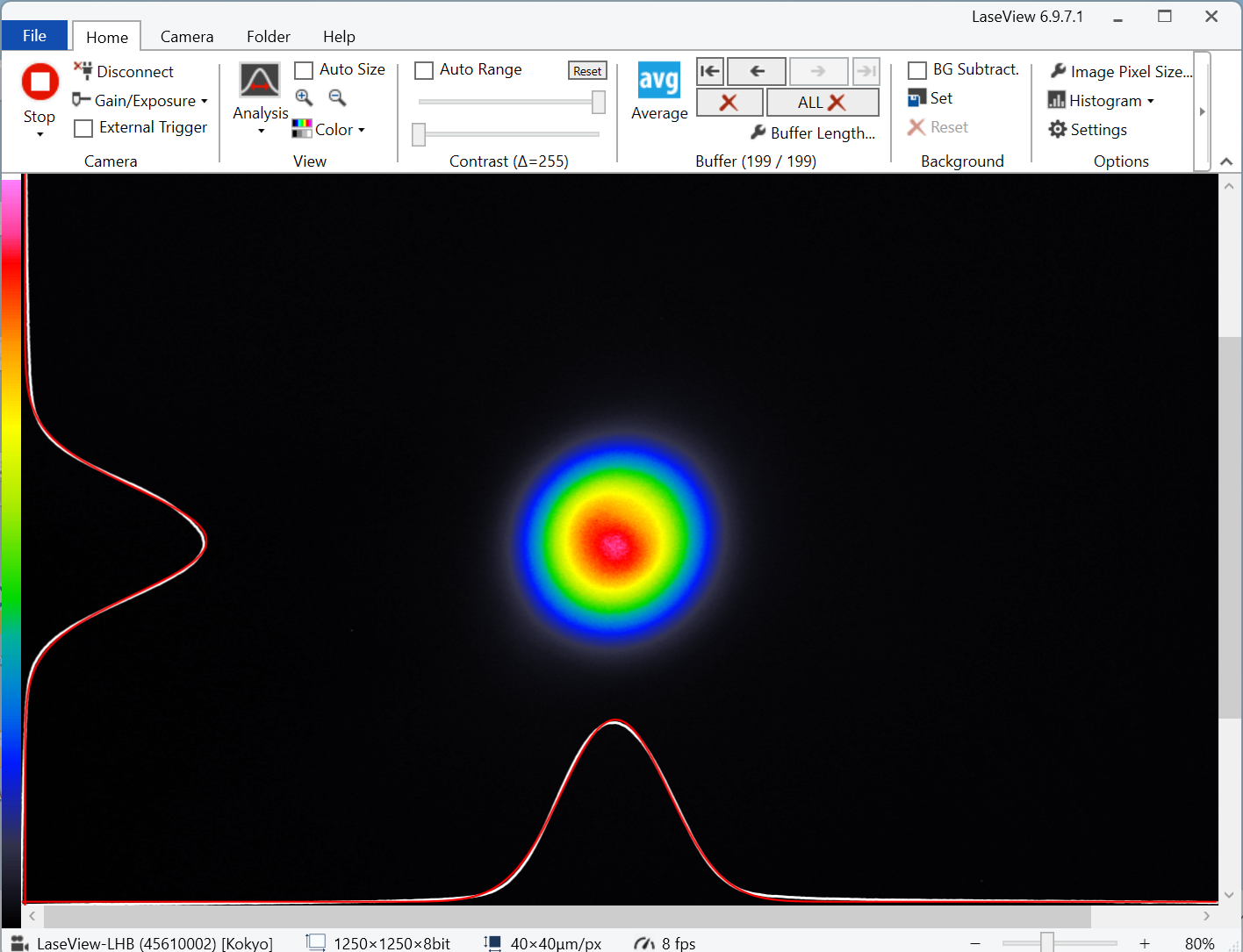

Integral profile function

Displays a profile averaged in the horizontal/vertical direction. The same analysis functions as the line profile can be used.

Maximum value projection profile function

Displays only the profile of the horizontal/vertical orthographic projection (maximum value). The same analysis functions as for line profiles can be used. In the figure, the FWHM is measured.

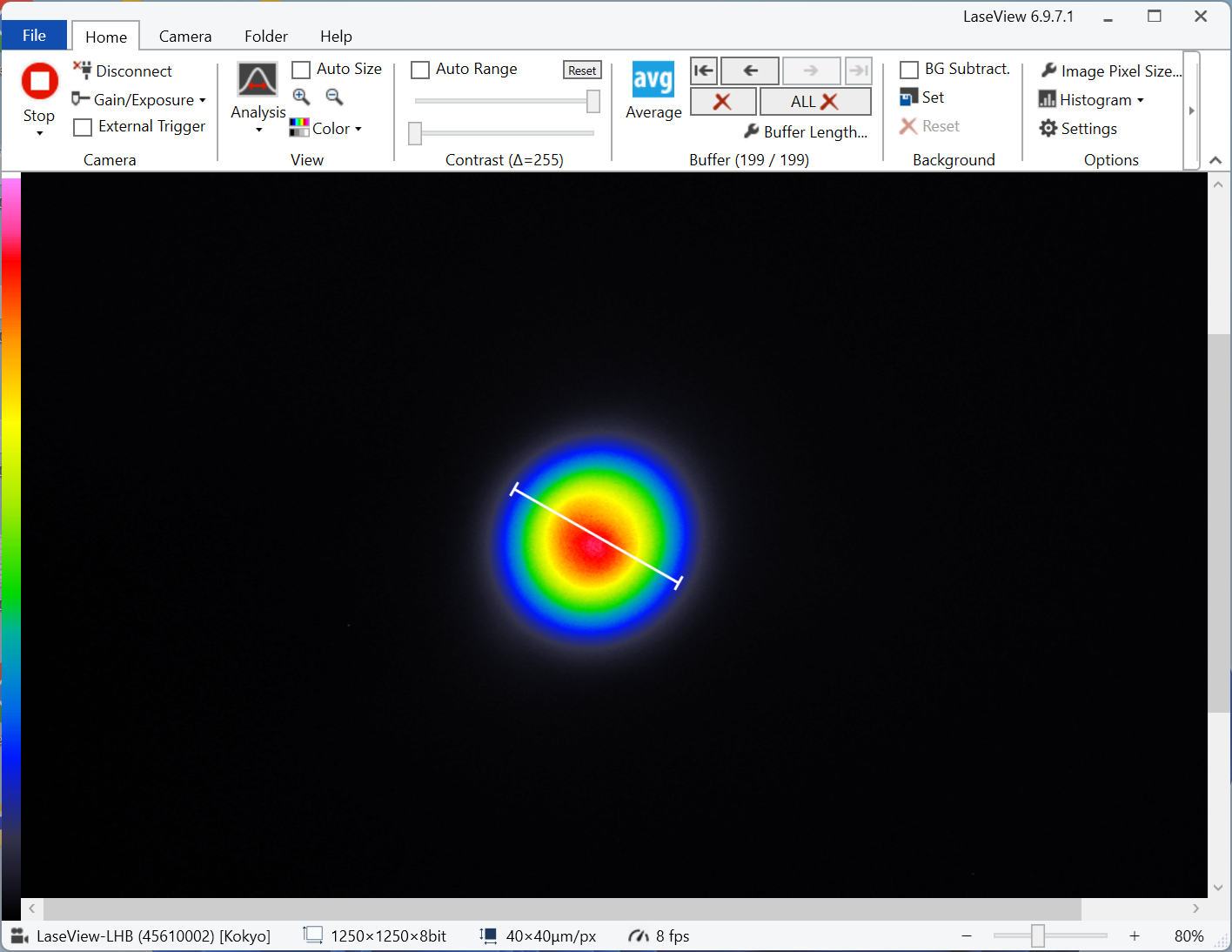

Point-to-point distance function

It is possible to measure the distance between any two points on the screen. In the figure below, you can see that the diameter of the profile shown in green is 826.8 μm.

Peak Integration Function

This function analyzes the integral value in the park with the outside of the circle as background. Adjust the position and size of the circle that appears on the screen so that the beam is well within the circle. When the ” Peak Detection” is clicked as shown in the figure below, the peak position will be indicated by the crosshair cursor.

Description of the notation

A description of the notation used in each function is shown in the table below.

| Function | Notation | Description |

|---|---|---|

| Line profiles Integral Profiles Maximum value projection profile |

FWHM X | Horizontal full width at half maximum |

| FWHM Y | Vertical full width at half maximum | |

| FW@1/e X | Full width at 1/e in horizontal direction | |

| FW@1/e Y | Full width at 1/e in vertical direction | |

| FW@1/e2 X | Full width at 1/(e×e) in horizontal direction | |

| FW@1/e2 Y | Full width at 1/(e×e) in vertical direction | |

| Center X | Horizontal center position | |

| Center Y | Vertical center position | |

| Height X | Horizontal peak height | |

| Height Y | Vertical peak height | |

| Position X | Horizontal cursor position | |

| Position Y | Vertical cursor position | |

| Integration Profile | Max X | Maximum value of horizontal signal strength |

| Min X | Minimum value of horizontal signal strength | |

| Max Y | Maximum value of vertical signal strength | |

| Min Y | Minimum value of vertical signal strength | |

| Point-to-Point Distance | Distance | Distance between two points (m) |

| Distance | Distance between two points (pixels) | |

| Pos. X1 | X-coordinate of the first point | |

| Pos. Y1 | Y-coordinate of the first point | |

| Pos. X2 | X-coordinate of the second point | |

| Pos. Y2 | Y-coordinate of the second point | |

| Peak Integration | Intensity /cm2 | Intensity at the cursor position (in cm^-2) |

| Raw Value | Digital count value of Intensity value | |

| Background | Background signal intensity | |

| Integral | Integral with background subtraction | |

| Raw Integral | Integral value without background subtraction | |

| Position X | Horizontal cursor position | |

| Position Y | Vertical cursor position |

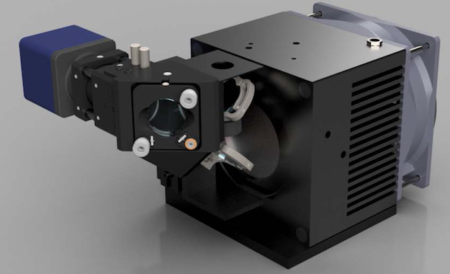

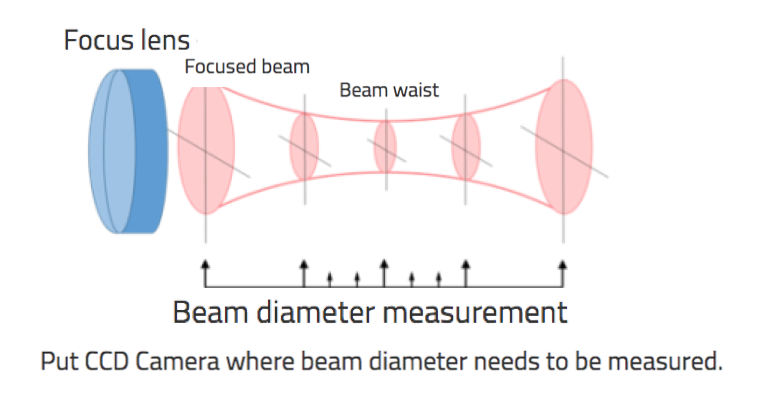

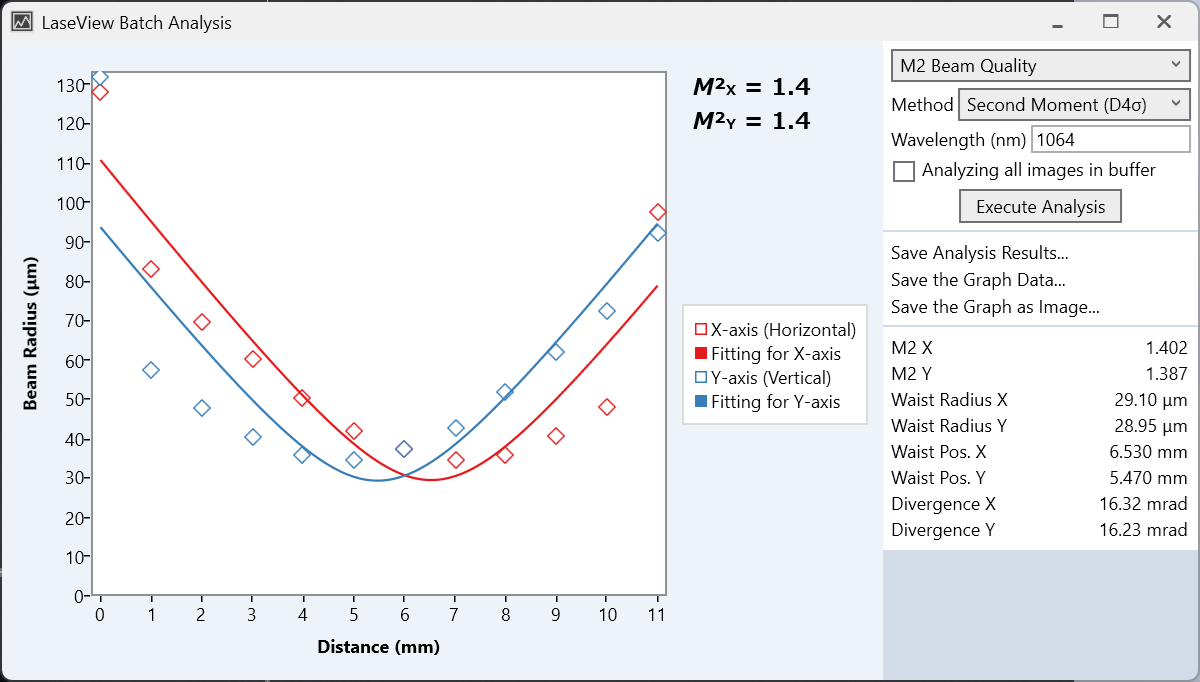

M2 beam quality analysis function

The procedure for setting up the optical system is shown below.

- Focus the laser beam using a lens with an F value (focal length/beam diameter) of about 50 to 100.

- Set up a ruler or optical rail so that the CCD camera can slide along the beam within ±50mm to ±150mm from the center of the beam waist.

- Adjust the incident light level and gain/exposure time so that the laser beam is not too strong.

The procedure for M2 beam quality analysis is shown below.

- Click “Open Folder” in the “File” tab and create (or specify) an empty folder to save the images.

- Save about 10 to 30 beam profiles on the axis of the laser beam, centered on the beam waist and ranging from ±50mm to ±150mm in front and behind. The procedure is as follows.

- Check the beam diameter at the beam waist.

- Move the CCD camera to a position where the beam diameter is about 5 times larger than the beam diameter at the beam waist.

- Fix the CCD camera and adjust the light intensity and CCD exposure time to obtain a good image with low noise.

- Click on “Save Image” in the “File” tab, enter the current CCD position in the file name text box (Please use single-byte character in China, Korea etc.), and save the image. At this time, the unit can be added after the number, such as nm, um, mm, cm, m. If the unit is omitted, the image will be processed as mm.

Example. 30mm.tif, 100mm.tif, 150mm.tif, etc. - The CCD camera is moved at intervals of 2 to 10 mm, and above step 3 to step 5 are repeated. In this case, the moving intervals do not have to be equal, and the accuracy may be improved by measuring the area around the beam waist at narrower intervals.

- Click the “M2 Beam Quality” button in the “Batch Analysis” tab, the M2 Beam Quality Analysis window will appear, and enter the laser wavelength in nm in the text box on the upper right.

- Click the “Run Analysis” button to run the analysis, and if successful, the results will be displayed in the graph.

*Analysis results are displayed as beam radius.

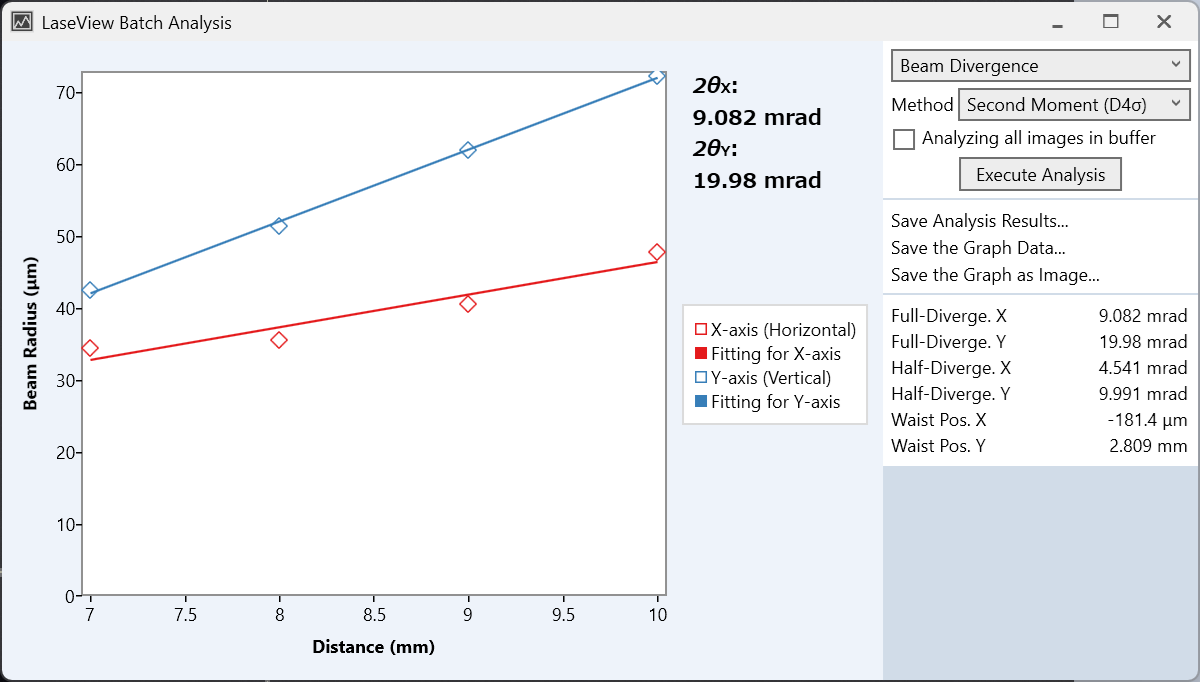

Beam divergence angle analysis

The procedure for beam divergence analysis is shown below.

- Click “Open Folder” in the “File” tab and create (or specify) an empty folder to save the images.

- Take measurements at two or more locations and save the images in the same folder. Include the measurement location in the file name. For example, 1.5 m, 25 cm, etc.

- “Click the [Spread Angle] button in the [Analyze] tab. The Batch Analysis window for the beam divergence angle appears.

- Click the [Run Analysis] button to run the analysis, and if successful, the results will be displayed in a graph.

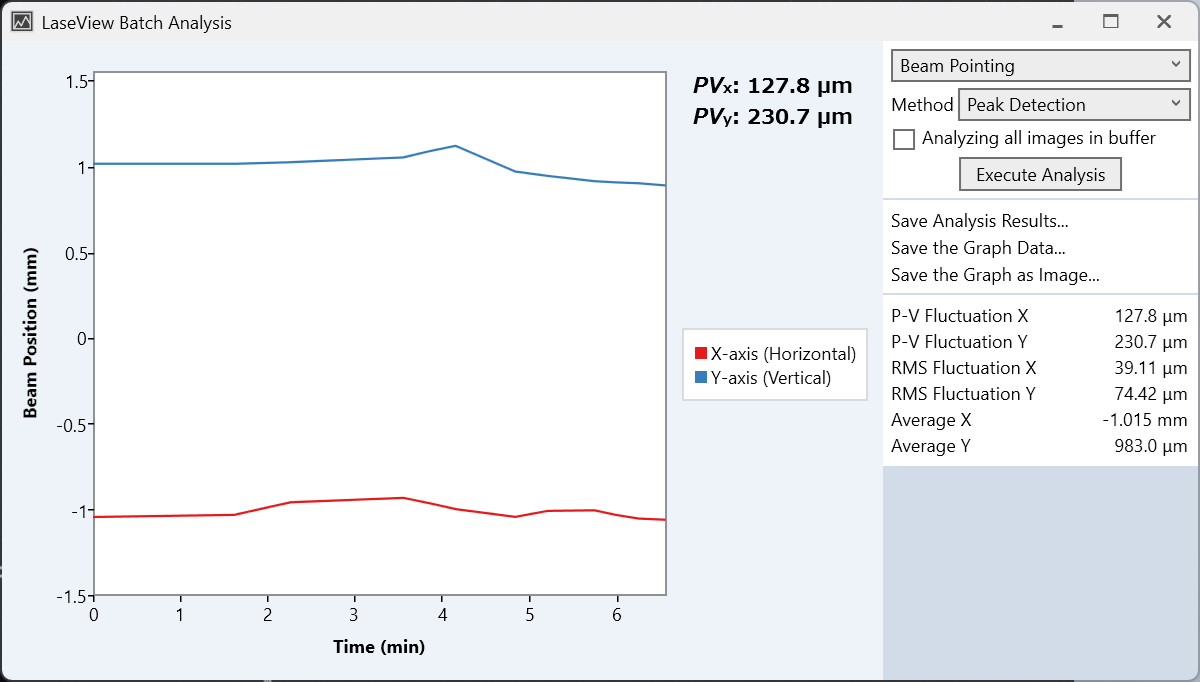

Analysis function of temporal beam pointing changes

The following is the procedure for analyzing the temporal beam pointing change.

- Click “Open Folder” in the “File” tab and create (or specify) an empty folder to save the images.

- Use the image logging function to save the images at reasonable time intervals.

- Click the “Pointing” button.

- Click “Run Analysis” to display a graph of the timed changes in the X and Y coordinates of the beam center. The elapsed time is calculated based on the shooting date and time embedded in the file.

Comparison with conventional product

By using commercially available CCD and CMOS cameras, an extremely low-cost and practical beam measurement system can be easily built. In addition, the availability of low-cost cameras makes it possible to construct a beam monitoring system with multiple cameras at low cost.

| LaseView | Conventional products | |

|---|---|---|

| Customizability | ◎ | ✕ |

| Sales system | Software only (Supported Cameras) | Software license and camera |

| Use of third party cameras | ◎ (Supported Cameras) |

✕ |

| Minimum measurable Beam diameter | from 2 μm (When the micro-beam measurement set is installed) |

from 30 μm |

| Maximum measurable beam diameter | within 200 mm (Sold as Laser Beam Profiler for large apertures and high power) |

within 24 mm |

| Maximum measurable power | within 600 W (Sold as 600 W Beam Profiler for Fiber laser) |

? |

| Languages | English captions are automatically shown if OS is not Japanese version | Fixed (English ?) |

Example of LaseView usage

When paired with a large beam profiler, the software handles stitching, distortion correction, and nonuniformity compensation across wide beam diameters. This makes it ideal for analyzing beams up to 800 mm in diameter.

See our LBP-B large beam profiler product pages for hardware details that integrate seamlessly with this software.

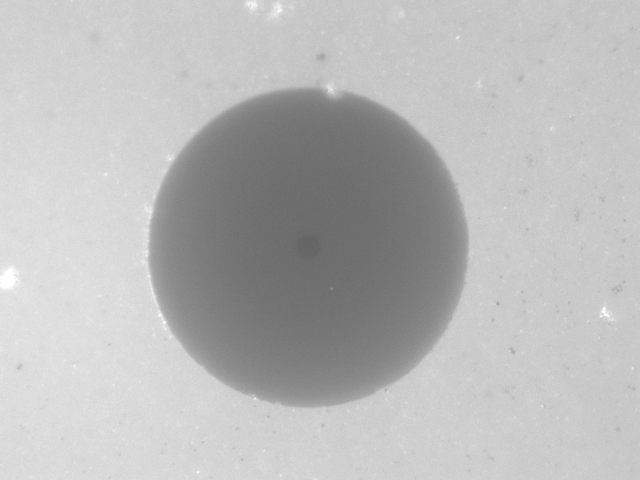

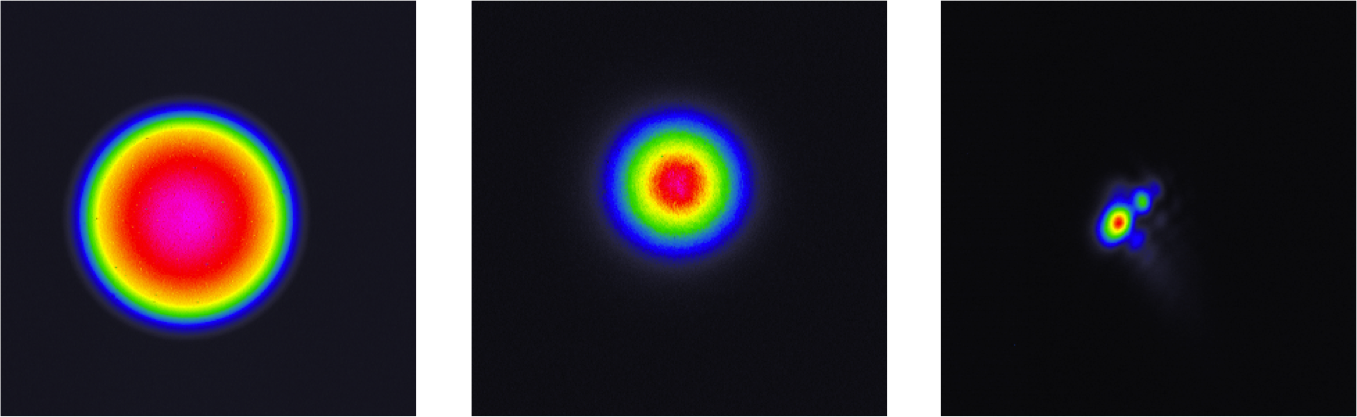

Sample images

Fig. from left : near-field image of a He-Ne laser, far-field image of a Ti:Sapphire laser (focused by a parabolic reflector with f=3.3), and focused LD light output from a multimode fiber.

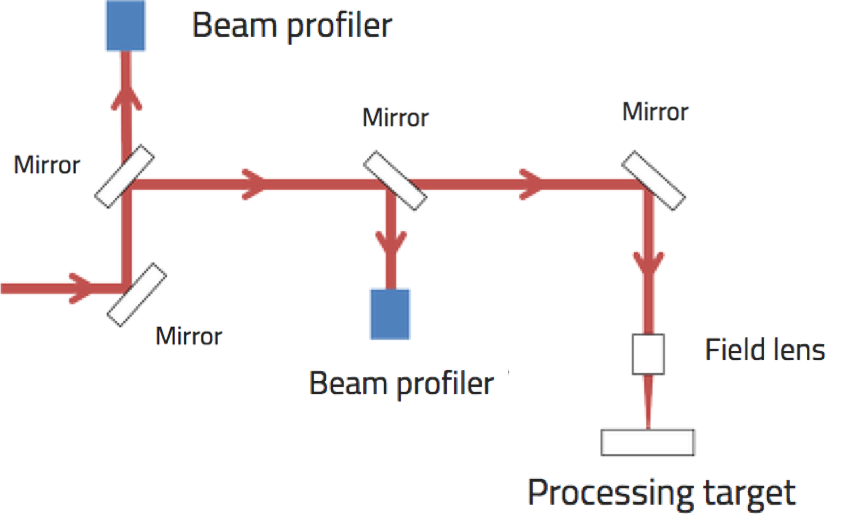

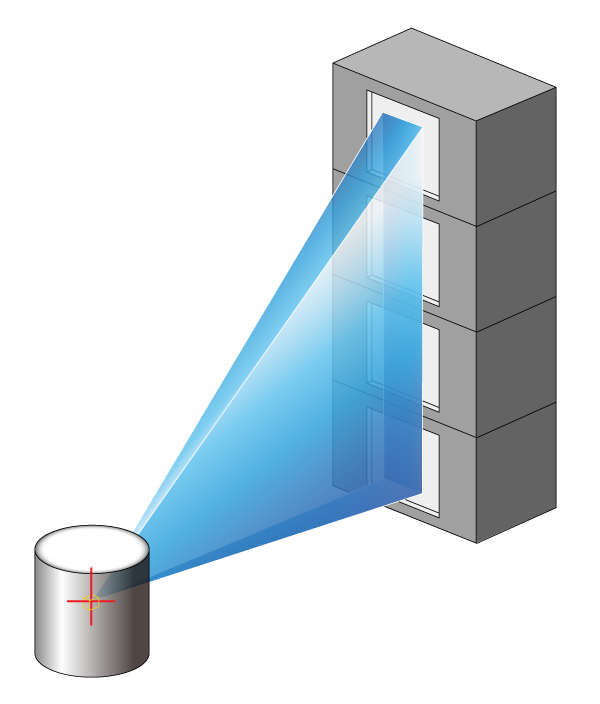

Laser beam position monitoring system for laser processing (1 software + 2 cameras)

Fig. Monitoring the position of the laser beam during laser processing.

In laser processing, the laser beam is transmitted as a collimated beam and then focused by a lens to irradiate the object. If the direction or position of the parallel beam incident on the lens changes, the position of the focusing point changes or the beam profile changes, resulting in inaccurate processing. To keep the beam direction (pointing vector) and the position of the beam center on the lens accurate, an optical system with two Laser Laser Beam Profiler is used. The position of the incoming parallel beam (e.g., the center of the beam) is measured at two locations, and precise optical axis adjustment is performed using two mirrors so that the beam is in position at both locations.

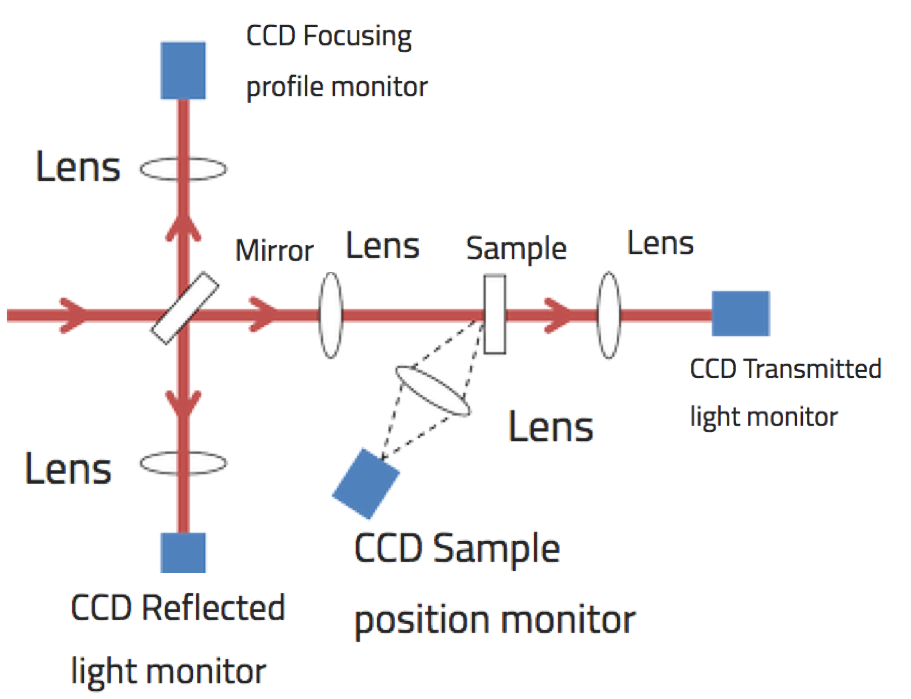

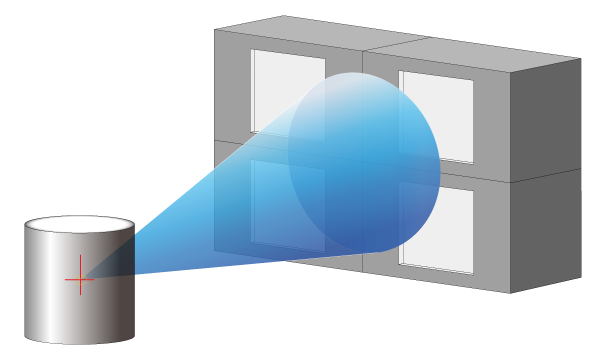

Laser beam monitoring system for laser processing (damage) testing (1 software + 4 cameras)

Fig. Measurement using multiple CCDs in a laser processing (damage) test.

In laser processing (damage) test, it is necessary to measure the beam profile accurately at the sample position and to determine whether or not damage has occurred after irradiation. In addition, positional reproducibility during sample exchange is important because of the large number of samples to be measured. Therefore, an optical system with multiple CCDs (Laser Beam Profiler) is used.(Note that LaseView can also be used for observation using a color CCD camera because it supports color image display.)

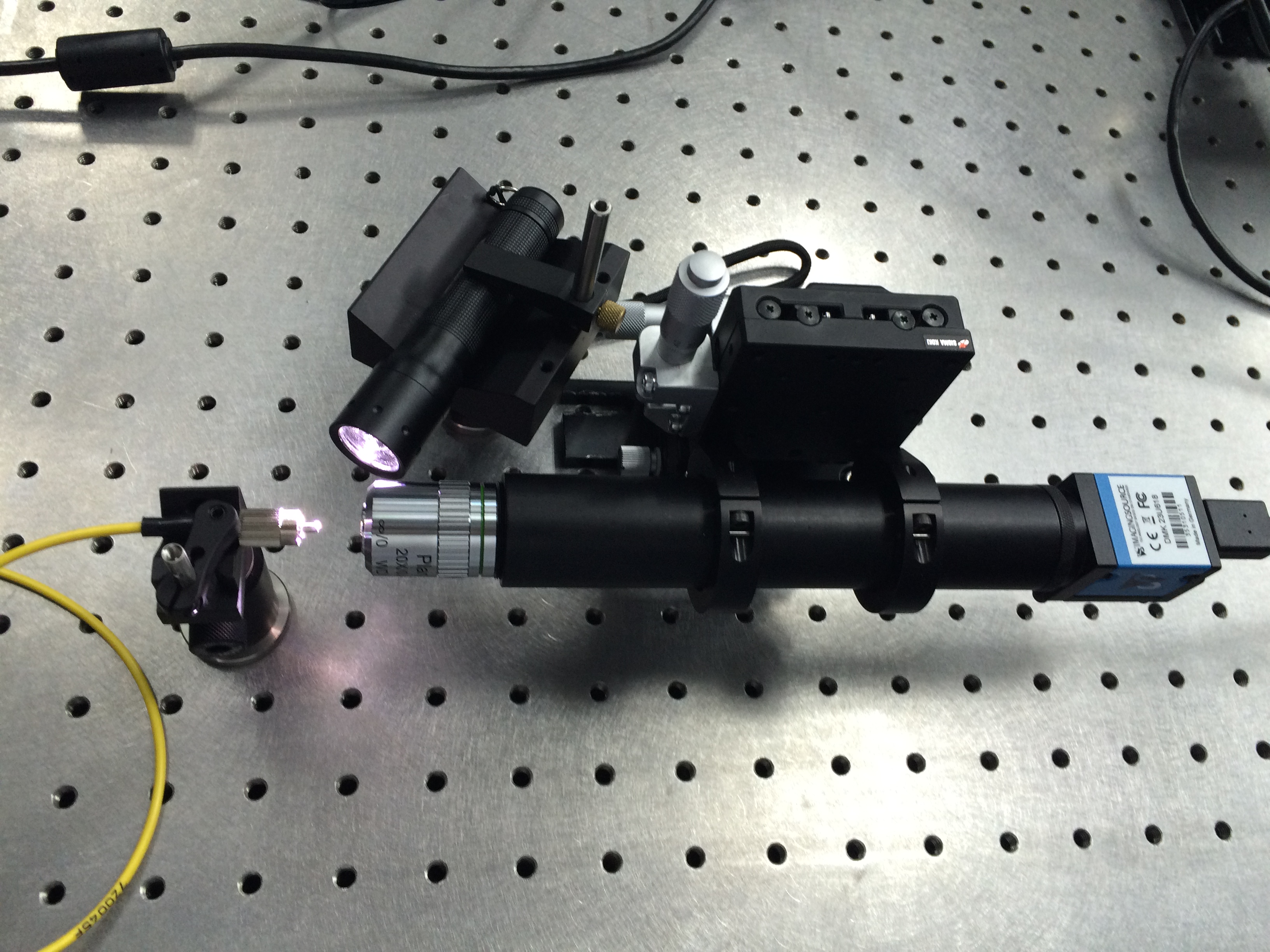

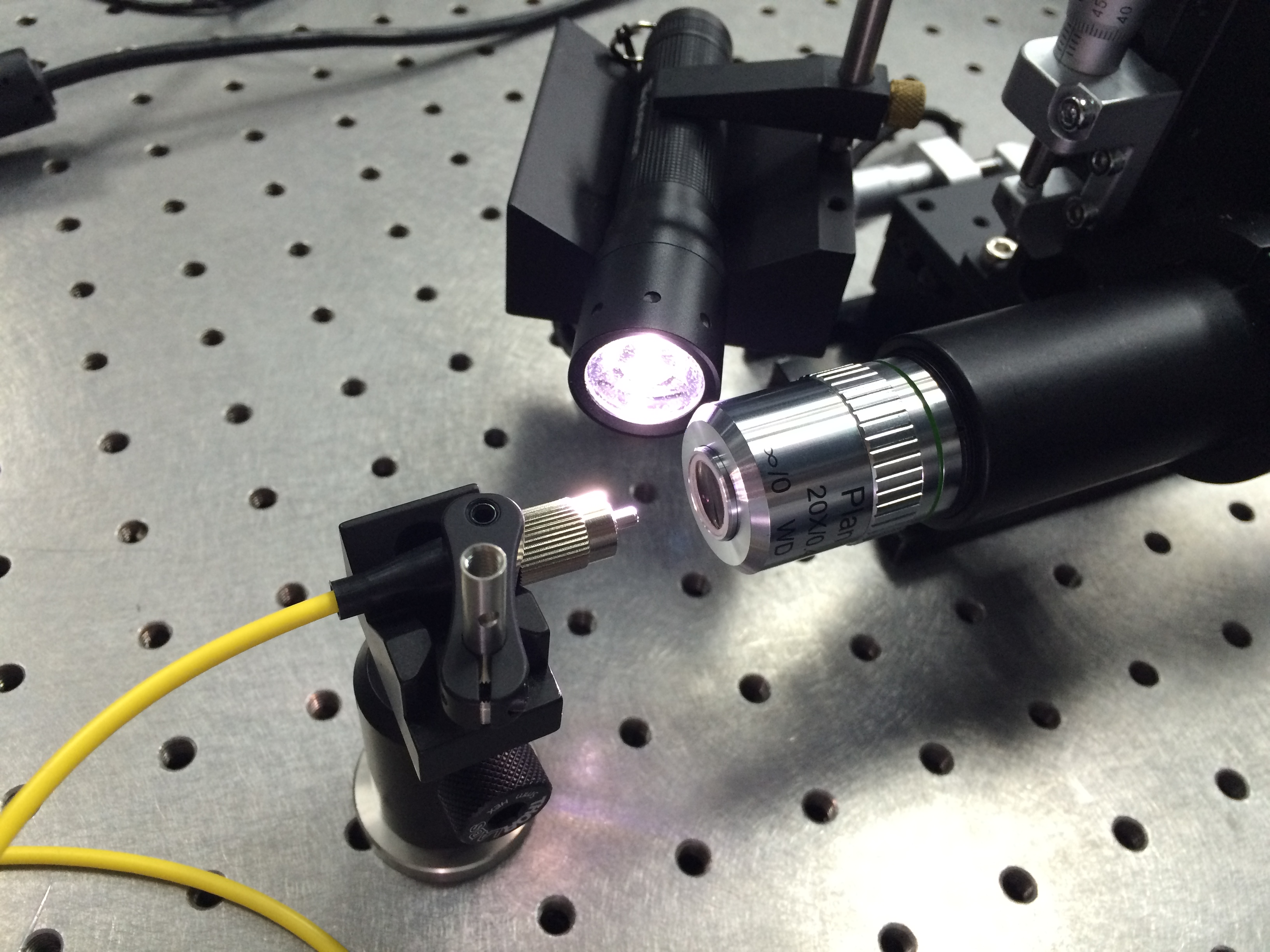

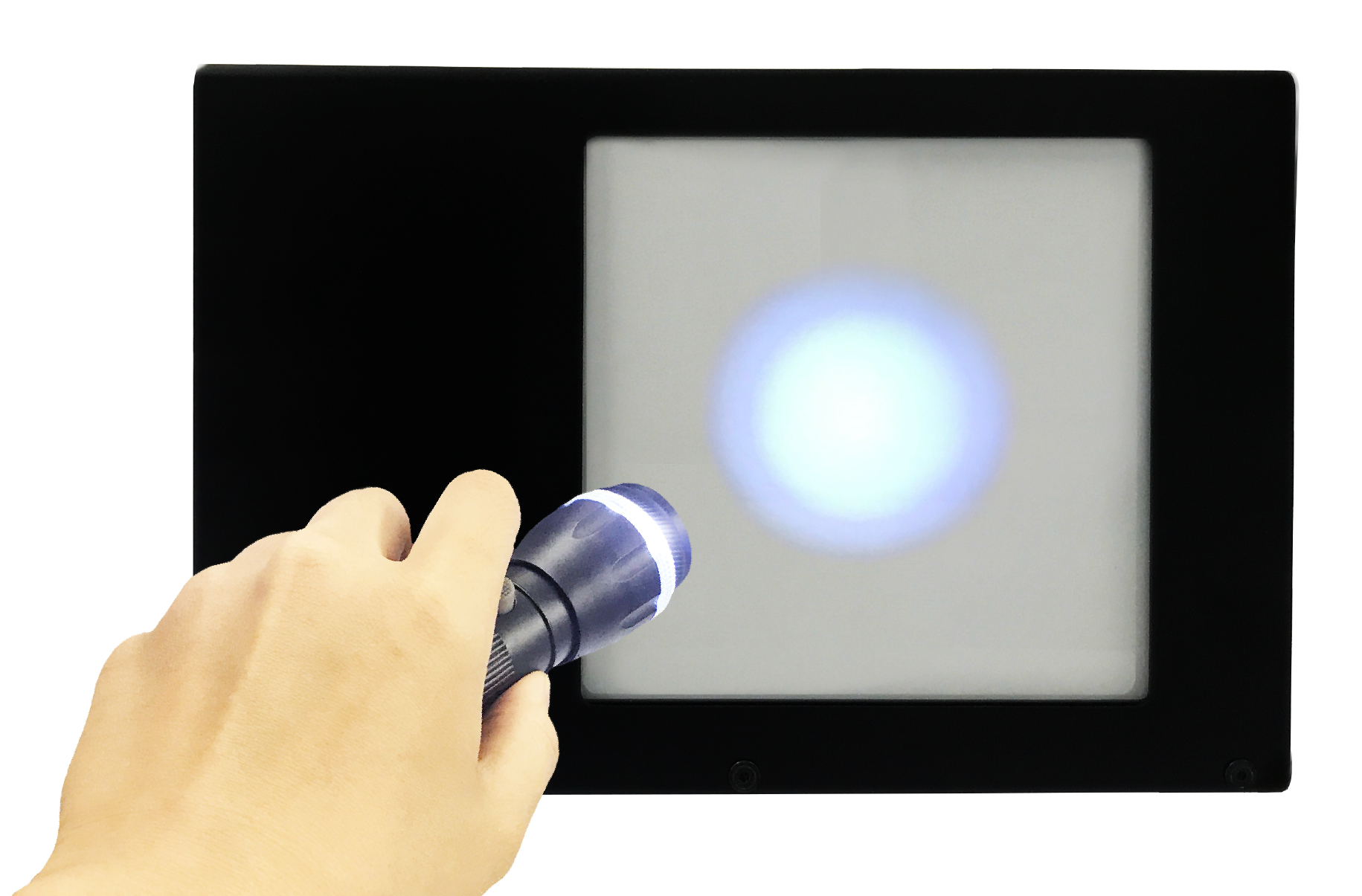

Optical microscope system

By simply attaching the optical tube to the CCD camera,Laser Beam Profiler can be used as a microscope. Chromatic aberration is corrected in the visible range (400 to 700nm). By using a color camera, full color display is possible, and by illuminating with LED lights, various objects such as fiber end facet can be observed.

- Magnification: 10x, 20x, 40x (specify magnification when ordering)

- NA: 0.25 (10x), 0.40 (20x), 0.65 (40x)

- Wavelength range: 400 to 700 nm

- Working distance: 5.5 mm (10x), 1.7 mm (20x), 0.6 mm (40x)

- Length: approx. 180 mm

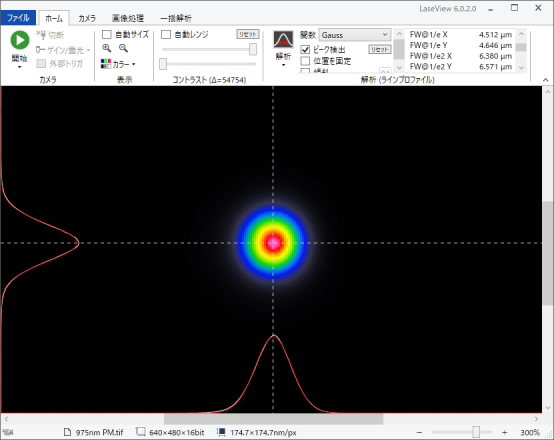

Optical fiber measurement system

A laser beam with a wavelength of 975 nm emitted from the end facet of an optical fiber (FC/APC connector) was measured with a microbeam optical system. The mode field diameter is found to be about 6.4 μm. This is consistent with the specification of the optical fiber (6.6 ± 0.7 μm @ 980 nm). It can also be seen that the measured intensity distribution (white line) and the Gaussian fitting (red line) are almost identical, although the near-field pattern of the HE11 mode is slightly different due to its Bessel function. The slight difference in the aspect ratio of the beam is due to the fact that the connector is obliquely polished. It can also be seen that the beam diameter in the transverse direction is reduced by refraction at the end of the fiber. It can see that

- there is no damage on the end facet of the optical fiber.

- the mode field diameter of the optical fiber is known.

- the intensity distribution is Gaussian.

- the connector is diagonally polished.

Optical fiber measurement system

Example of beam profile emitted from fiber facet

Control and Evaluation System for Spatial Light Modulator (LCOS-SLM)

Laser Beam Profiler software for evaluation was integrated into the CGH program software for LCOS-SLM control developed by us.

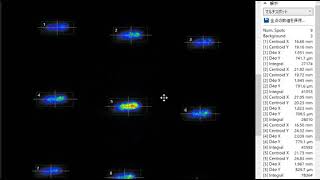

LaseView’s multi-point analysis function

It is possible to analyze multiple beam spots simultaneously with a single camera (See video). This function greatly enhances the quality of LiDAR.

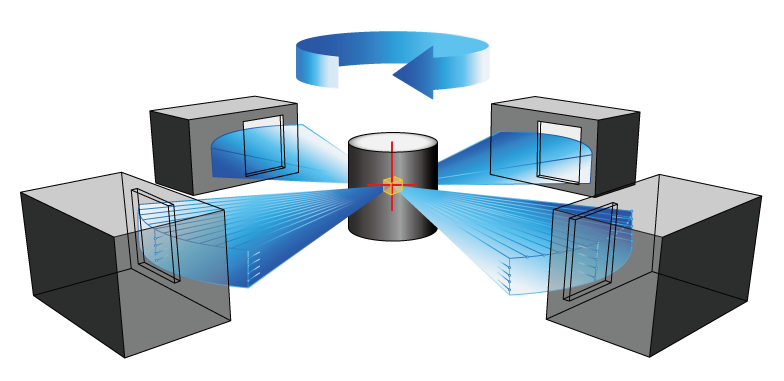

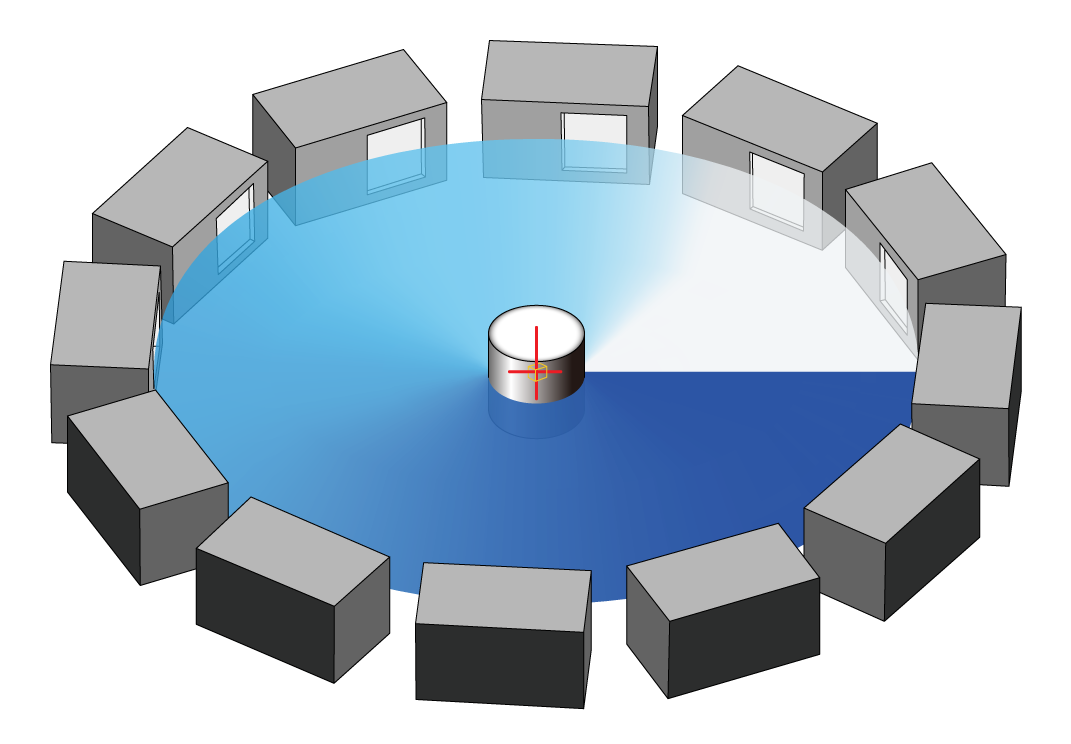

Evaluation system of LiDAR using multiple LHB

This availability helps to analyze LiDAR’s spatial distribution.

Case1 Example of using analysis with multiple LHBs

Placed at 90 degrees each in the circumferential direction

Case2 Example of using analysis with multiple LHBs

Placed 4 for each quarter of the circumferential direction.

Case3 Example of using analysis with multiple LHBs

Stacked 4 vertically.

Case4 Example of using analysis with multiple LHBs

Arranged in the matrix state

Seminar movie

Webinar video of our participation in “Measurement Solution Web Seminar 2020 – For Measurement of Film, Coating and Light Source” hosted by Cybernet Systems, Inc. (Above site is only in Japanese.)

Introduction of the large aperture Laser Beam Profiler (LaseView-LHB) for evaluation of laser scanners, LiDAR

Sales results of LaseView

- Jet Propulsion Laboratory, NASA

- Continuum Inc.

- LG Electronics

- Wontech

- Avision(Suzhou)CO.,LTD. Mechanical Engineering.Sect.2

- Helmholtz-Zentrum Dresden-Rossendorf (HZDR, Germany)

- Institute of Physics AS CR, v.v.i. (Czech Republic)

- University of Southampton (United Kingdom)

- Hong Kong Precision Industry Co.

- Osaka University

- Kyushu University

- Kyoto University

- Kyoto Institute of Technology

- Shinshu University

- Nagoya University

- University of Electro-Communications

- The University of Tokyo

- Tokyo Institute of Technology

- Sophia University

- The Graduate University for the Creation of New Photonics Industries

- Hiroshima University

- University of Fukui

- Yamagata University

- University of the Ryukyus

- Utsunomiya University

- Institute of Physical and Chemical Research

- National Institute of Laser Technology

- National Institute of Advanced Industrial Science and Technology (AIST)

- Japan Atomic Energy Agency

- National Institute of Information and Communications Technology

- Japan Aerospace Exploration Agency

- Quantum Science and Technology Research Organization

- National Astronomical Observatory of Japan (NAOJ)

- Japan Coast Guard Headquarters

- Information equipment and industrial optical system development manufacturers

- Optical product research and development manufacturer

- Other domestic and foreign private companies

Reviews

- The camera is inexpensive, so don’t worry about breaking it.

- Camera can be used as disposable.

- Easy to prepare.

- The software is intuitive and easy to use.

- Inexpensive.

- M2 beam quality measurement is included as a standard feature, which is very nice.

- The evaluation results showed that the software works as expected, so we have just ordered the software. (used the evaluation version before purchasing)

Distributors

We have distribution channels of “Laser Beam Profiler LaseView series” as below.

Dylan Hong

CTL GLOBAL

327, 5, Beobwon-ro 4-gil, Songpa-gu, Seoul, Korea

Tel : +82 070 7779-4500

Fax : +82 42 367 4300

yshong@ctloptics.com

www.youtube.com/channel/UCsovG44FeikIp-zYfLZP3uw

ctl.imweb.me

Bernd Dietz

Geschäftsführer / Managing Director

nortus Optronic GmbH

In den Niederwiesen 4a

D-76744 Wörth am Rhein

Tel : +49-7271-12990-0

Fax : +49-7271-12990-19

info@nortus-optronic.com

www.nortus-optronic.de

If you want to be a distributor, please contact us.

info@symphotony.com